How Do Collaborative Welding Robots Differ from Traditional Industrial Robots?

Automation is becoming essential in modern manufacturing, especially in welding operations. As industries look for better productivity and safer work environments, two main types of robotic systems are commonly used: collaborative welding robots and traditional industrial robots. Understanding the difference between these two helps factory owners choose the right solution for their production needs.

What Are Traditional Industrial Welding Robots?

Traditional industrial robots have been used in manufacturing for decades. These robots are designed for high-speed, high-volume production. They are powerful, fast, and capable of handling heavy welding applications continuously.

However, because of their speed and strength, traditional welding robots must operate inside safety cages or fenced areas. Human workers are not allowed inside the working zone while the robot is active. This setup ensures safety but limits flexibility.

Traditional robots are ideal for:

-

Large automotive production lines

-

High-volume repetitive welding

-

Heavy structural fabrication

-

Long continuous welding cycles

They usually require skilled engineers for programming and maintenance. Any change in production may require reprogramming and downtime.

What Are Collaborative Welding Robots?

Collaborative welding robots, often called cobots, are designed to work safely alongside humans in the same workspace. Unlike traditional robots, they are equipped with advanced sensors that detect contact, force, and human presence.

If a worker comes too close or touches the robot, it automatically slows down or stops. This eliminates the need for heavy safety cages in many applications.

Collaborative welding robots are commonly used in:

-

Small and mid-scale manufacturing units

-

Automotive component fabrication

-

Custom or short-batch production

-

Flexible production environments

They are easier to program and operate. Many systems allow hand-guiding or simple interface programming, reducing the need for advanced robotics expertise.

Key Differences Between Collaborative and Traditional Welding Robots

1. Safety and Workspace

Traditional industrial robots must operate behind barriers due to high speed and force. Collaborative robots are built with safety sensors that allow shared workspace operation.

For small factories with limited floor space, collaborative systems are often more practical.

2. Speed and Payload Capacity

Traditional robots are generally faster and can handle heavier welding applications. They are suitable for high-output automotive assembly lines.

Collaborative robots operate at slightly lower speeds for safety reasons but offer better flexibility for smaller production volumes.

3. Programming and Setup

Traditional welding robots require skilled technicians for programming. Production changes can take time.

Collaborative welding robots are easier to set up. Operators can quickly teach new welding paths, making them ideal for businesses handling varied product designs.

4. Investment and ROI

Traditional robotic welding systems usually involve higher initial investment due to fencing, infrastructure, and complex integration.

Collaborative welding robots are often more affordable and easier to integrate, making them attractive for small-scale manufacturers looking for gradual automation.

Which One Is Right for Your Factory?

The right choice depends on your production volume, floor space, and operational goals.

If you run a high-volume automotive manufacturing line, traditional industrial robots may deliver maximum speed and efficiency.

If you operate a flexible manufacturing unit in Coimbatore or Tamil Nadu with varying product designs, collaborative welding robots can offer better adaptability and quicker return on investment.

Many manufacturers are now consulting experienced automation companies in Coimbatore to evaluate which robotic system fits their long-term strategy.

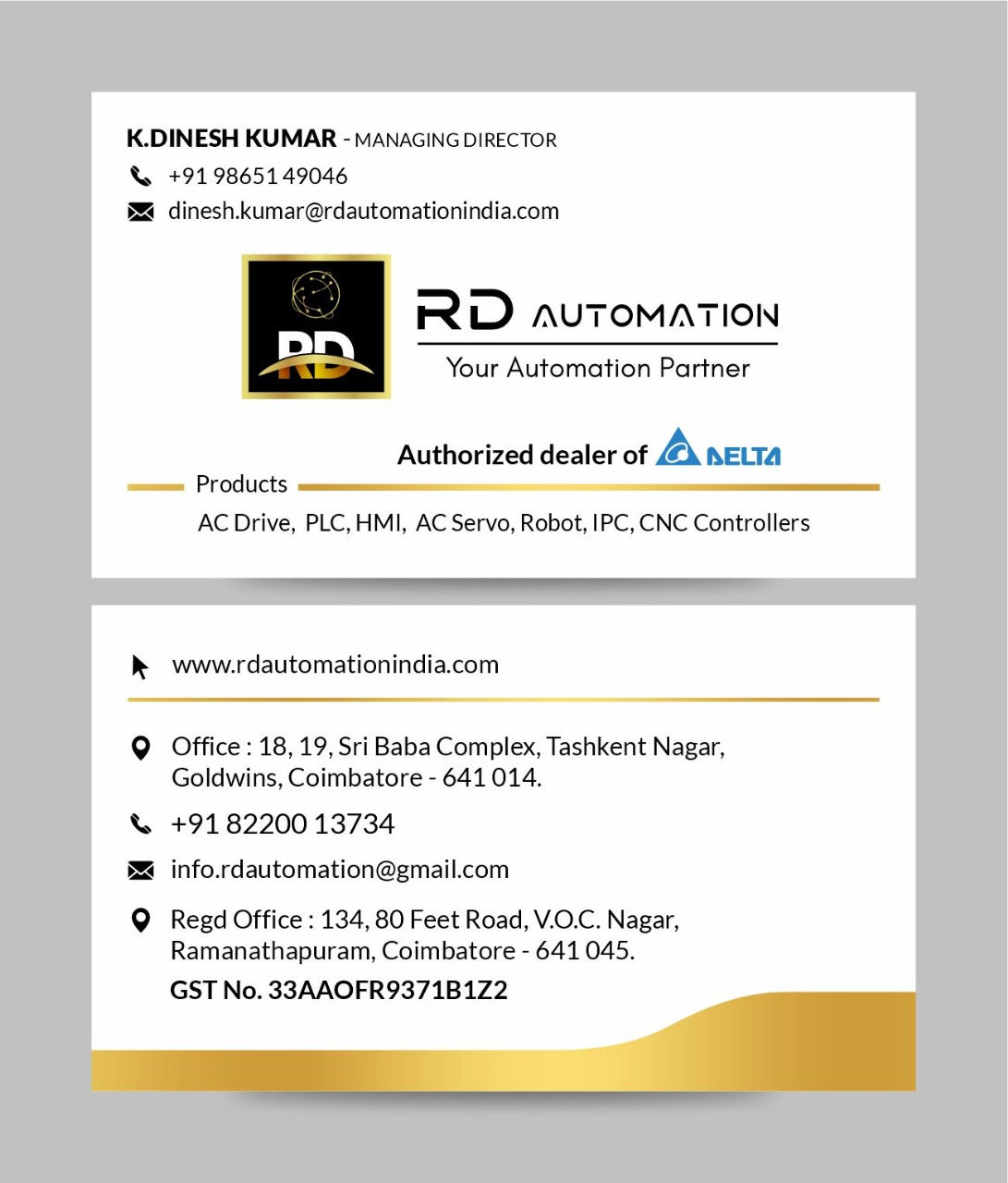

Companies like RD Automation help factory owners assess welding requirements, production targets, and workspace constraints before recommending either collaborative or traditional robotic solutions.

Final Thoughts

Both collaborative welding robots and traditional industrial robots have important roles in modern welding automation. Traditional robots provide unmatched speed and heavy-duty performance, while collaborative robots offer flexibility, safety, and ease of use.

As manufacturing continues to evolve, choosing the right automation partner becomes just as important as choosing the right robot. With proper planning and expert guidance, factories can improve productivity, reduce errors, and create safer working environments.

Automation is not just about replacing manual work. It is about building a smarter and more efficient production system that supports long-term growth.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness