Leading ABS Sheets Manufacturers in India – ISO Certified | Polestar Polymers India

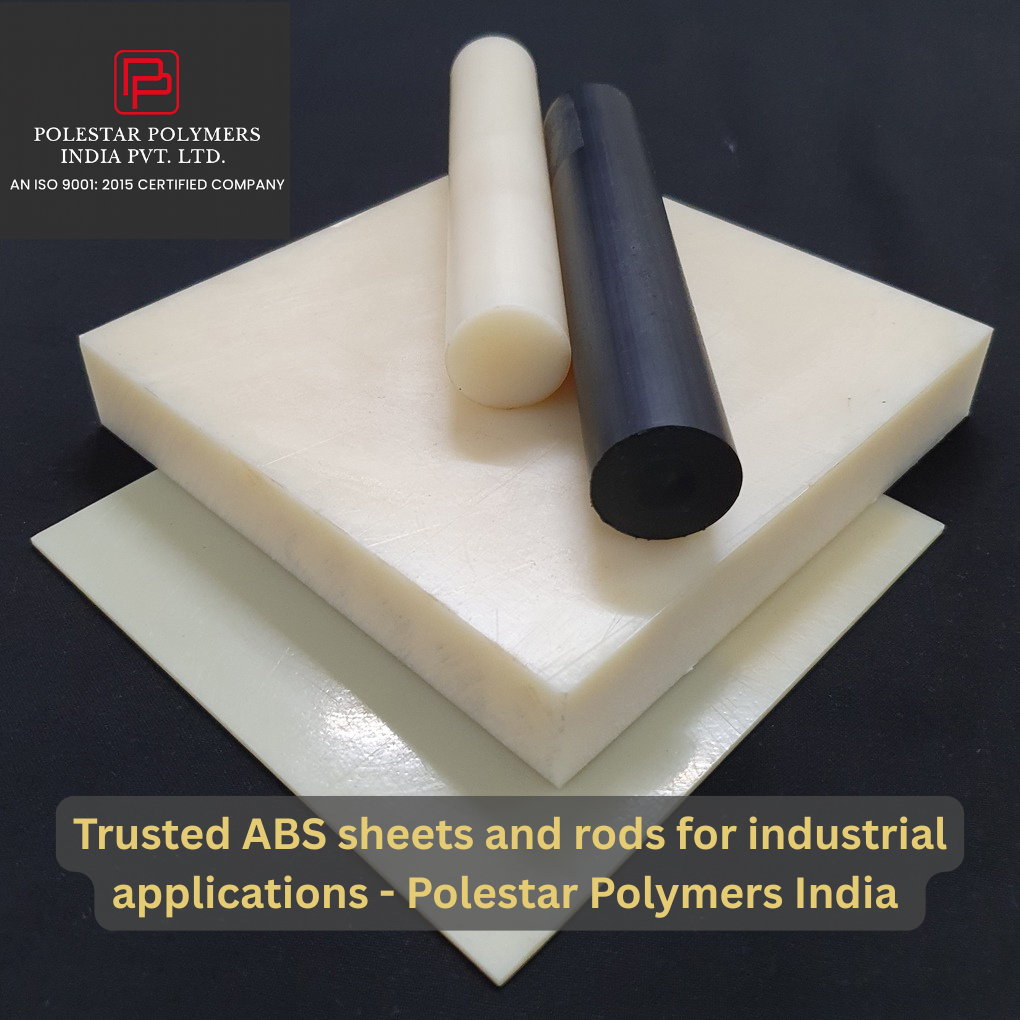

ABS Sheets Manufacturers in India: Why Polestar Polymers Is the Trusted Choice for Industrial ABS Sheets

When industries look for high-impact, durable, and precision-engineered plastic sheets, ABS Sheets consistently top the list. From automotive parts and machine components to enclosures and prototypes, ABS (Acrylonitrile Butadiene Styrene) has become one of the most preferred engineering thermoplastics. If you’re searching for ABS Sheets manufacturers in India, choosing the right supplier matters just as much as choosing the material itself. This is where Polestar Polymers India Pvt. Ltd. stands out — a name trusted by manufacturers, OEMs, and fabricators across the country.

What Are ABS Sheets and Rods? Why Are They So Widely Used?

ABS Sheets are manufactured from Acrylonitrile Butadiene Styrene, a high-performance thermoplastic known for its excellent impact strength, rigidity, and machinability.

ABS Rods are preferred for turned and machined components such as bushes, spacers, rollers, guides, and structural parts. Their solid cylindrical form allows for precise machining on lathes and CNC machines, offering excellent toughness and resistance to cracking under load.

Unlike brittle plastics, ABS offers a balanced combination of:

- Strength

- Toughness

- Dimensional stability

- Smooth surface finish

This makes ABS Sheets & Rods suitable for both functional and aesthetic applications.

Key Properties of ABS Sheets & Rods

- High impact resistance, even at low temperatures

- Easy to machine, drill, cut, and fabricate

- Good thermal stability

- Can be painted, bonded, and electroplated

- Good mechanical strength with balanced rigidity for structural applications

- Can be cut, drilled, milled, turned, and fabricated without cracking

- Consistent surface quality for industrial parts

These qualities explain why ABS is widely used in engineering, automotive, electrical, and machinery sectors.

ABS Rods, on the other hand, are preferred for turned and machined components such as bushes, spacers, rollers, guides, and structural parts. Their solid cylindrical form allows for precise machining on lathes and CNC machines, offering excellent toughness and resistance to cracking under load.

Growing Demand for ABS Sheets Manufacturers in India

India has emerged as a strong manufacturing hub for engineering plastics, and ABS Sheets are no exception. Industries today demand custom sizes, consistent quality, and dependable supply, which only experienced manufacturers can deliver.

The rise in demand for ABS Sheets manufacturers in India is driven by:

- Growth in automotive and EV components

- Expansion of industrial machinery manufacturing

- Increased use of CNC-machined plastic components

- Demand for lightweight, corrosion-resistant alternatives to metal

However, not all ABS sheet suppliers offer the same quality standards. This is why working with an ISO-certified manufacturer becomes crucial.

Applications of ABS Sheets Across Industries

Thanks to their versatile properties, ABS Sheets are used in a wide range of industrial applications:

✔ Automotive Industry

Used for dashboards, trims, covers, and non-structural components requiring impact resistance.

✔ Machine Parts & Covers

Ideal for CNC-machined components, guards, and protective housings.

✔ Prototyping & Product Development

ABS Sheets are easy to machine and modify, making them perfect for prototypes.

✔ Electrical & Industrial Enclosures

ABS offers good insulation properties and structural integrity for enclosures.

Why Quality Matters When Buying ABS Sheets in India

When sourcing ABS Sheets, low-quality material can lead to:

- Cracking during machining

- Warping under load

- Inconsistent thickness

- Poor surface finish

This is why experienced ABS Sheets manufacturers in India like Polestar Polymers focus on:

- Controlled manufacturing processes

- Certified quality standards

- Material consistency across batches

For industrial buyers, this translates into lower rejection rates, smoother machining, and longer product life.

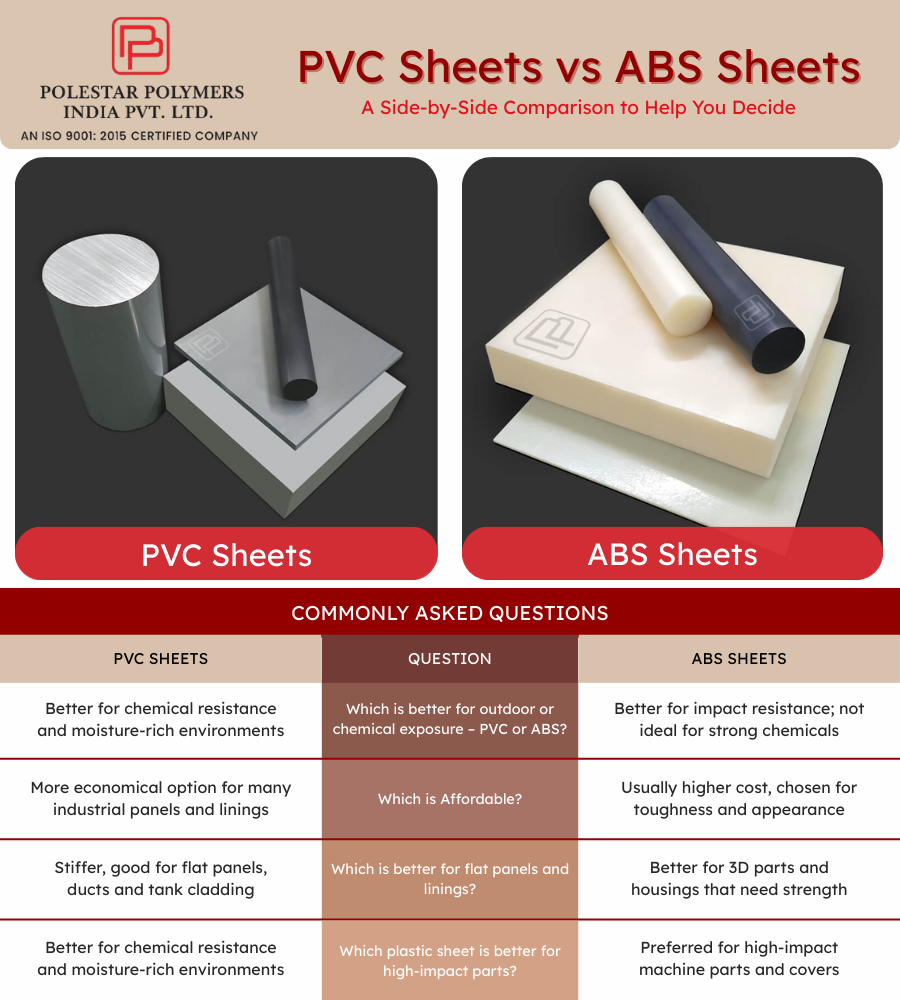

ABS Sheets vs PVC Sheets: Key Differences Every Buyer Should Know

Choosing between ABS Sheets and PVC Sheets often depends on the application rather than price alone.

PVC Sheets are commonly selected for:

- Chemical resistance

- Moisture-rich environments

- Cost-sensitive panel and lining applications

ABS Sheets, on the other hand, are preferred when:

- Impact resistance is critical

- Strength and toughness are required

- Machined or 3D-shaped components are involved

In simple terms, PVC excels in chemical environments, while ABS dominates in mechanical and structural applications. This comparison helps buyers quickly shortlist the right material before diving into detailed specifications.

Why Polestar Polymers Is a Preferred ABS Sheet Supplier

What truly sets Polestar apart is their application-first approach. Instead of offering generic plastic sheets, they focus on end-use performance.

Clients choose Polestar Polymers because they get:

- Technical guidance for material selection

- Custom cutting and machining support

- Reliable delivery timelines

- Long-term supply consistency

This makes them more than just ABS Sheets manufacturers in India — they are engineering partners.

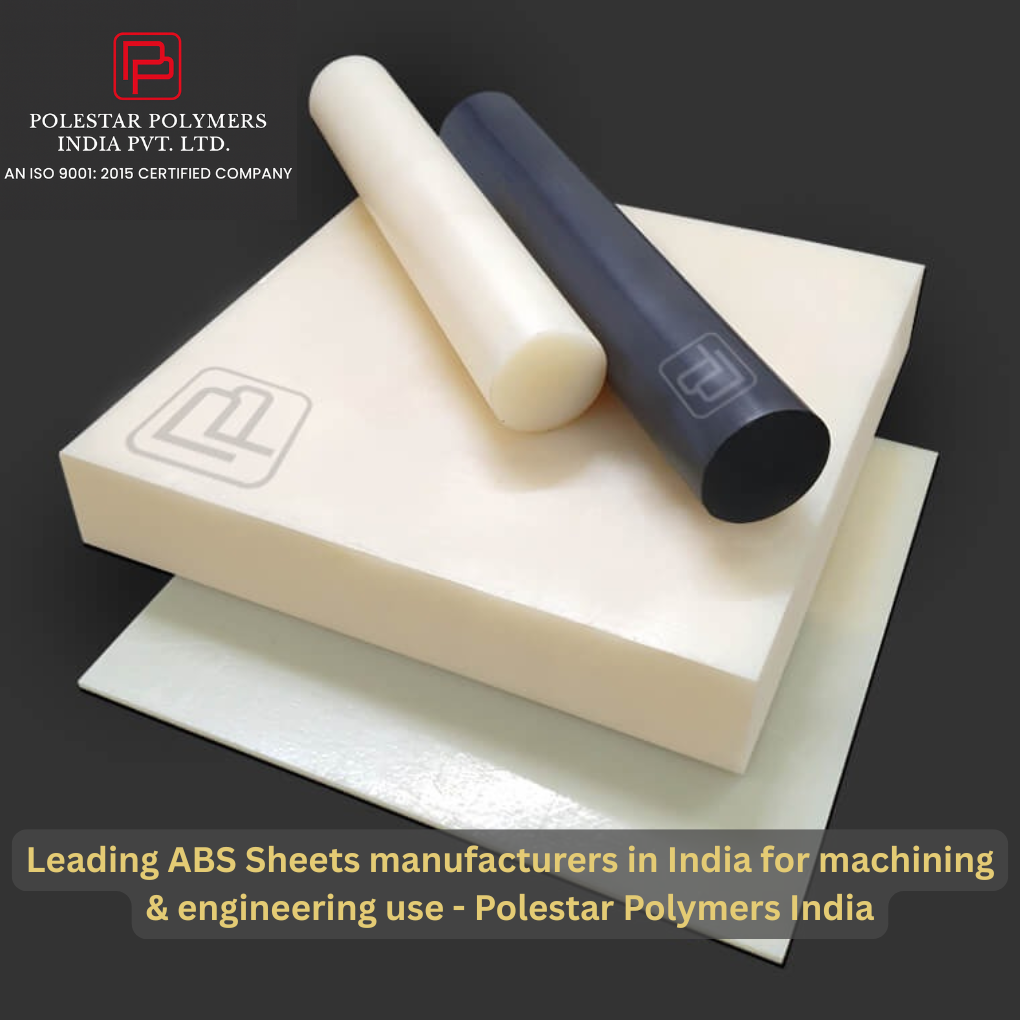

Polestar Polymers India Pvt. Ltd. – A Trusted Name Among ABS Sheets Manufacturers in India

Polestar Polymers India Pvt. Ltd. is an ISO 9001:2015 certified company specialising in engineering plastic sheets and rods. Their STELLO B (ABS) Sheets are designed for applications where performance, precision, and durability are non-negotiable.

Why Choose Polestar Polymers for ABS Sheets?

1. Engineering-Grade ABS Sheets

Polestar focuses on Machine Grade / Engineering Grade ABS, ensuring superior mechanical properties and dimensional accuracy.

2. Wide Size & Thickness Range

ABS Sheets are available in:

- Thickness: 2 mm to 150 mm

- Width: Up to 620 mm

- Length: Up to 2440 mm

This flexibility reduces material wastage and improves fabrication efficiency.

3. In-House Machining Capability

Unlike many ABS Sheets manufacturers in India, Polestar offers in-house machining services, allowing customers to receive ready-to-use components as per drawings.

4. Consistent Quality & Surface Finish

Each ABS sheet is produced with strict quality control, ensuring:

- Uniform thickness

- Smooth finish

- Reliable performance in demanding environments

5. Trusted Across Industries

Polestar ABS Sheets are widely used in:

- Automotive components

- Prototype models

- Machine parts and covers

- Industrial enclosures

Frequently Asked Questions (FAQs)

1. Who are the leading ABS Sheets manufacturers in India?

Polestar Polymers India Pvt. Ltd. is among the most trusted ABS Sheets manufacturers in India, known for engineering-grade ABS sheets and in-house machining support.

2. What is the standard thickness of ABS Sheets?

ABS Sheets are commonly available from 2 mm to 150 mm, depending on the application and manufacturer.

3. Are ABS Sheets suitable for CNC machining?

Yes. ABS Sheets from Polestar Polymers offer excellent machinability, making them ideal for CNC and precision components.

4. What industries use ABS Sheets the most?

Automotive, machinery manufacturing, electrical enclosures, and prototyping industries are major users of ABS Sheets.

5. Are ABS Sheets chemical resistant?

ABS has moderate chemical resistance but is primarily chosen for impact strength and mechanical performance, not aggressive chemical environments.

6. Can ABS Sheets be painted or finished?

Yes. ABS Sheets can be easily painted, bonded, and surface-finished for aesthetic applications.

7. How do ABS Sheets compare to PVC Sheets?

ABS Sheets are better for impact and strength-based applications, while PVC Sheets are preferred for chemical resistance and moisture exposure.

Looking for Reliable ABS Sheets?

If you’re sourcing high-quality ABS Sheets for industrial, automotive, or machining applications, Polestar Polymers India Pvt. Ltd. are Trusted ABS Sheets Manufacturer that offers the right combination of material quality, technical expertise, and manufacturing capability.

👉 Explore ABS Sheets here:

https://polestarpolymers.com/abs.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness