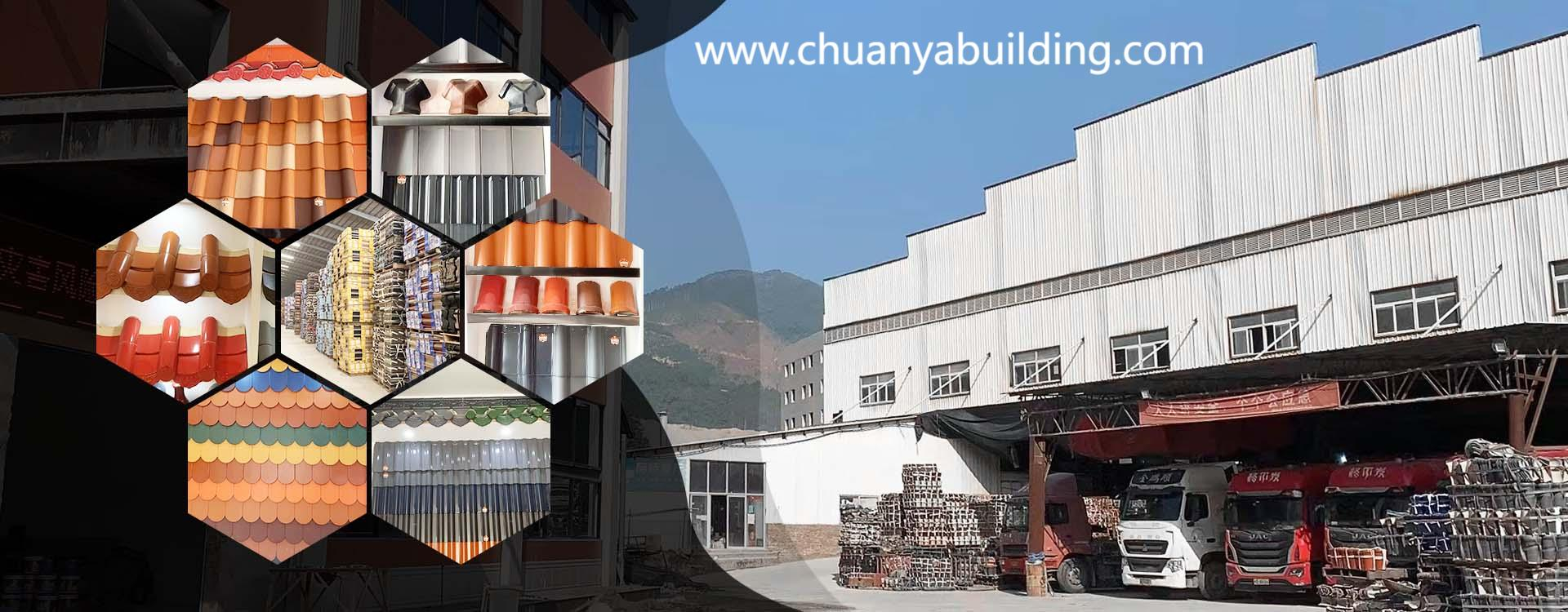

chuanyabuilding China Roof Tile Factory In Industrial Planning

In discussions surrounding industrial construction and material sourcing, the topic of China Roof Tile Factory selection is frequently raised when chuanyabuilding becomes part of early planning conversations, yet how many decision makers truly consider the broader implications of factory origin at the very beginning of a roofing project?

Roofing systems represent more than surface coverage. They form an interface between structural integrity, environmental exposure, and long term maintenance expectations. When sourcing begins at the factory level, project teams gain insight into production rhythm, coordination capacity, and material continuity, all of which influence downstream execution.

Manufacturing environments shape outcomes long before installation begins. The organization of production lines, the stability of processing routines, and the alignment between design intent and fabrication practice collectively determine how roofing components perform visually and functionally once integrated into a building envelope.

Supply continuity is a recurring industry concern. Roofing projects often operate within phased schedules, requiring materials to arrive in sequence rather than as isolated shipments. Factories capable of synchronized planning contribute to smoother transitions between construction stages, reducing uncertainty during critical milestones.

Architectural consistency depends on controlled production. When roofing components originate from unified manufacturing conditions, surface appearance and dimensional alignment remain coherent across large scale developments, supporting design intent without introducing visual fragmentation.

Project adaptability increasingly influences material selection. As construction environments evolve due to site conditions or regulatory interpretation, responsive manufacturing coordination allows adjustments to be addressed without destabilizing overall schedules or design frameworks.

Environmental consideration now shapes industrial dialogue. Roofing materials connected to responsible production practices align with broader planning objectives that seek harmony between built structures and surrounding contexts, especially in regions emphasizing sustainable development pathways.

Quality evaluation extends beyond final inspection. Transparent process oversight, traceable workflows, and internal verification mechanisms establish confidence across procurement phases, supporting informed decision making rather than reactive correction.

Logistical strategy plays a decisive role in material condition upon arrival. Packaging methodology, handling protocols, and transport preparation directly influence how roofing components integrate on site, particularly for projects operating across long distances or variable climates.

Communication clarity remains essential throughout project lifecycles. Factories that provide structured documentation and responsive coordination help bridge gaps between design, procurement, and construction teams, allowing collaboration to proceed with fewer interpretive challenges.

chuanyabuilding participates in roofing discussions by emphasizing coordination value, production stability, and contextual alignment within industrial construction planning. For additional insights related to factory evaluation considerations, visit https://www.chuanyabuilding.com/news/industry-news/the-ultimate-guide-to-choosing-the-right-china-roof-tile-factory.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness