Global Fleet Management Platform: Tech Trends & Operational Benefits

Think about the complex systems that keep our daily lives running, fresh produce reaching stores, parts arriving at factories, or online orders landing at our doorsteps. It’s all made possible by carefully planned, but often invisible, transportation networks.

As global expectations shift toward greater speed, real-time visibility, and flawless precision, traditional systems and manual processes are being stretched to their limits.

This shift brings both pressure and potential for the people who keep everything moving: transporters, fleet owners, and 3PL providers, the real engineers of modern transportation and logistics networks. But many still rely on outdated methods, scattered data, reactive firefighting, and gut instincts instead of digital intelligence.

To navigate this new reality, the old playbook simply won’t work anymore. The future of robust and reliable supply chains hinges on a fundamental reengineering of transport operations. This blog uncovers precisely how technology is revolutionizing transporter operations, empowering them to build the resilient, responsive, and utterly precise logistical infrastructure that the modern world demands.

Key Challenges Transporters Face

Transporters are the backbone of logistics. Yet, they often face a unique set of challenges that affect service quality, efficiency, and profitability. Despite rising demand and increasing digitalization across the supply chain, transporter operations remain bogged down by inefficiencies that can and should be addressed through smarter digital platforms, such as dispatch and scheduling software and route optimization software for logistics.

Manual Processes Leading to Delays and Errors

Many transporters still handle bookings, dispatches, and trip records using paperwork and disconnected workflows. Key details like delivery times, vehicle availability, or trip costs are often jotted down in logbooks or typed into spreadsheets. These tools don’t offer real-time updates or easy collaboration.

This outdated method slows down daily tasks and increases the chance of errors, like duplicate entries, wrong addresses, or missing documents. Without a single digital system, it’s hard to coordinate between drivers, fleet managers, and clients. This often leads to late dispatches and missed service slots.

It also makes scaling tough. When everything runs on manual coordination, even a small spike in workload can cause delays, confusion, and miscommunication.

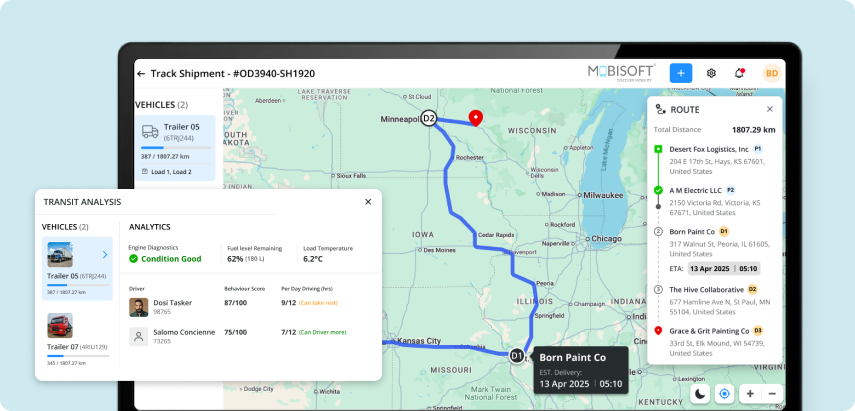

Lack of Real-Time Tracking and Customer Communication

Today’s customers want to know exactly where their shipments are. But many transporters don’t have the tools to offer real-time updates or track vehicles accurately, especially without cloud-based transportation management systems that offer GPS visibility and event-based alerts.

Without GPS or digital communication tools, they rely on calls and messages to get shipment updates. This takes time and often leads to mixed or delayed information.

As a result, transporters get constant calls from clients asking, “Where is my load?” Delays or route changes usually go unnoticed until they become serious issues. The lack of real-time visibility breaks customer trust and puts pressure on teams to manually trace every shipment.

READ MORE: Inefficient Fleet and Driver Management

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness