Increasing Packaging Efficiency Needs Driving Growth in the Global Liner Bag Market

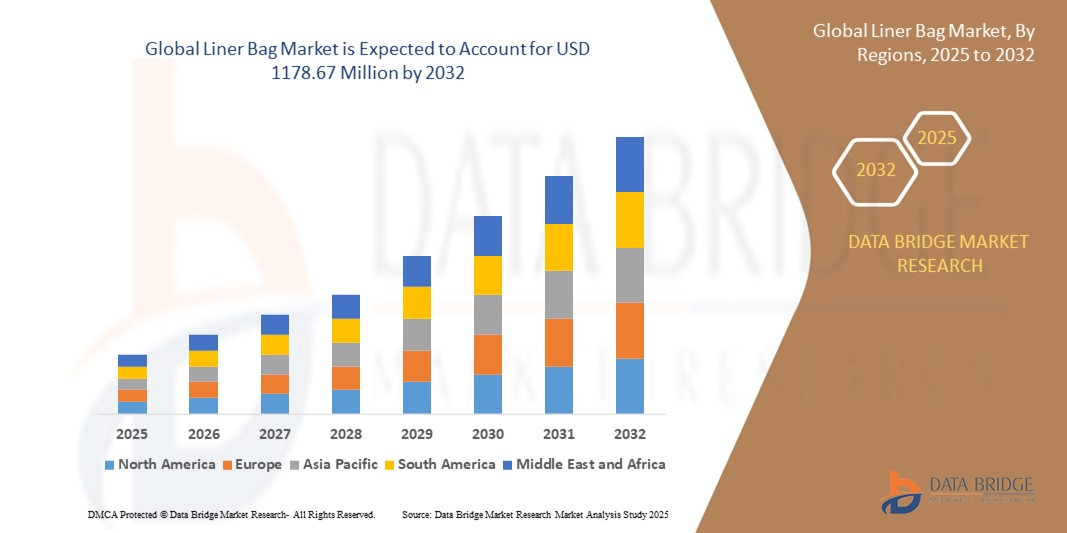

Liner bags play a crucial role in the protection, storage, and transportation of a wide range of goods, especially bulk materials that require enhanced containment. Designed for durability, hygiene, and contamination resistance, these bags are widely used across industries such as chemicals, agriculture, food processing, pharmaceuticals, and construction. As sustainability trends grow and flexible packaging solutions continue to outperform rigid alternatives, the liner bag market is positioned for notable expansion. The market is expected to grow from USD 835.20 million in 2025 to USD 1,178.67 million by 2032, registering a CAGR of 4.40% during the forecast period.

Rising Demand for Hygienic and Protective Packaging Solutions

Liner bags are essential in industries handling sensitive or high-volume products that require controlled environments during storage and transportation. These bags act as protective layers inside bulk containers such as drums, boxes, and flexible intermediate bulk containers (FIBCs). Their ability to prevent moisture, dust, and contamination makes them indispensable for transporting chemicals, resin, powders, fertilizers, grains, and pharmaceuticals.

Request a sample of Liner Bag Market report @ https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-liner-bag-market

In the food and agriculture sectors, liner bags support safe grain storage, dry ingredient packaging, and bulk supply chain efficiency. Their moisture-resistant barrier helps preserve product quality, reduce spoilage, and maintain shelf life. Meanwhile, the chemical industry relies heavily on liners to store hazardous and non-hazardous materials safely.

Innovations such as anti-static liners, thermal liners, biodegradable liners, and high-strength polyethylene materials continue to enhance durability, sustainability, and performance. As industries adopt modern, hygienic, and efficient packaging solutions, the demand for liner bags grows steadily.

Key Drivers Supporting Market Growth

- Increased Adoption of Bulk Packaging

Industries shifting toward large-volume packaging solutions fuel the demand for durable liner bags.

- Rising Food and Agricultural Production

Growing global food supply chains require moisture-resistant and contamination-proof packaging.

- Expansion of the Pharmaceutical and Chemical Industries

Strict safety and hygiene standards make liner bags essential for regulated materials.

- Growing Focus on Sustainability

Recyclable and biodegradable liner bag innovations boost market acceptance.

- Advancements in Material Technologies

Enhanced polyethylene, woven structures, and multi-layer barrier films improve bag strength and product protection.

Major Applications of Liner Bags

- Food & Agriculture

Used for grains, sugar, flour, seeds, and powdered products requiring contamination-free packaging.

- Chemical Industry

Ensures safe handling of powders, resins, pigments, and corrosive materials.

- Construction Materials

Liner bags store cement, sand additives, and industrial powders without leakage or spoilage.

- Pharmaceuticals

Provide sterile, protective containment for sensitive ingredients.

- Bulk Transportation & Warehousing

Liners act as interior layers in FIBCs, facilitating safer and cleaner logistics operations.

Inquire here to explore industry-specific data @ https://www.databridgemarketresearch.com/inquire-before-buying?dbmr=global-liner-bag-market

Leading Companies Operating in the Liner Bag Market

Key companies shaping the global liner bag industry include:

- Aristo Flexi Pack

- GLOBAL-PAK

- National Bulk Bag

- A-Pac Manufacturing

- Plascon

These manufacturers focus on high-quality barrier materials, customizable designs, anti-static features, and industrial-strength durability. Their products support industries requiring safe, compliant, and efficient packaging solutions. Continuous innovation in eco-friendly liners and advanced polymer processing further strengthens their market footprint.

Emerging Trends Influencing the Liner Bag Market

- Growing Demand for FIBC-Compatible Liner Bags

Industries increasingly use FIBCs, boosting the need for matching liners for enhanced protection.

- Expansion of Sustainable Packaging

Bio-based and recyclable liners meet rising environmental standards.

- Innovations in Anti-Static and Conductive Liners

Essential for industries handling volatile or electro-sensitive materials.

- Increased Customization for Industry-Specific Requirements

Tailored sizes, barrier properties, and material grades enhance usability.

- Adoption of Thermal and Insulated Liners

Supports temperature-sensitive supply chains such as pharmaceuticals and food ingredients.

BUY NOW @ https://www.databridgemarketresearch.com/checkout/buy/global-liner-bag-market/compare-licence

Importance of Liner Bags in Global Packaging and Supply Chain Efficiency

Liner bags provide significant advantages that support industrial productivity, safety, and sustainability:

- Protection from moisture, contamination, and environmental exposure

- Compliance with safety and hygiene regulations

- Reduction in product waste and storage losses

- Enhanced portability and warehouse efficiency

- Versatility across multiple industries

- Cost-effective alternative to rigid packaging solutions

As global supply chains expand and industrial activity intensifies, liner bags remain critical for safe storage and transportation of bulk materials.

Frequently Asked Questions (FAQ)

- What is a liner bag and what is it used for?

A liner bag is a protective inner layer placed inside containers or bulk bags to safeguard products from contamination, moisture, and leakage.

- Which industries commonly use liner bags?

Major users include agriculture, chemicals, food processing, pharmaceuticals, construction, and logistics.

- Are liner bags recyclable?

Many modern liner bags are made from recyclable polyethylene, and eco-friendly options are increasingly available.

- What factors are driving the growth of the Liner Bag Market?

Industrial bulk packaging demand, food safety requirements, and advances in barrier film technology are major contributors.

- How do liner bags improve supply chain efficiency?

They reduce product loss, protect quality, support safe transportation, and simplify warehouse handling.

- What materials are most liner bags made from?

Polyethylene (PE) and polypropylene (PP) are the most common, with specialized liners offering anti-static or thermal properties.

Access the full Liner Bag Market Report here @ https://www.databridgemarketresearch.com/reports/global-liner-bag-market

For More Reports

Polyethylene Terephthalate (PET) Lidding Films Market

Polypropylene Packaging Films Market

About Us

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact

Data Bridge Market Research Private Ltd.

3665 Kingsway — Suite 300

Vancouver BC V5R 5W2

Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)

Email: Sales@databridgemarketresearch.com

Website: https://www.databridgemarketresearch.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness