The Role of IoT Connectivity in Transforming Industrial Condition Monitoring

Online vibration monitoring systems have become essential across industries where equipment reliability, performance optimization, and predictive maintenance are top priorities. These systems track vibration levels in machinery in real time to detect early signs of wear, imbalance, misalignment, and mechanical faults. By identifying issues before they escalate, organizations can reduce downtime, improve operational safety, and extend machinery lifespan. As industries move toward digital transformation and automated maintenance solutions, online vibration monitoring technology continues to gain widespread adoption.

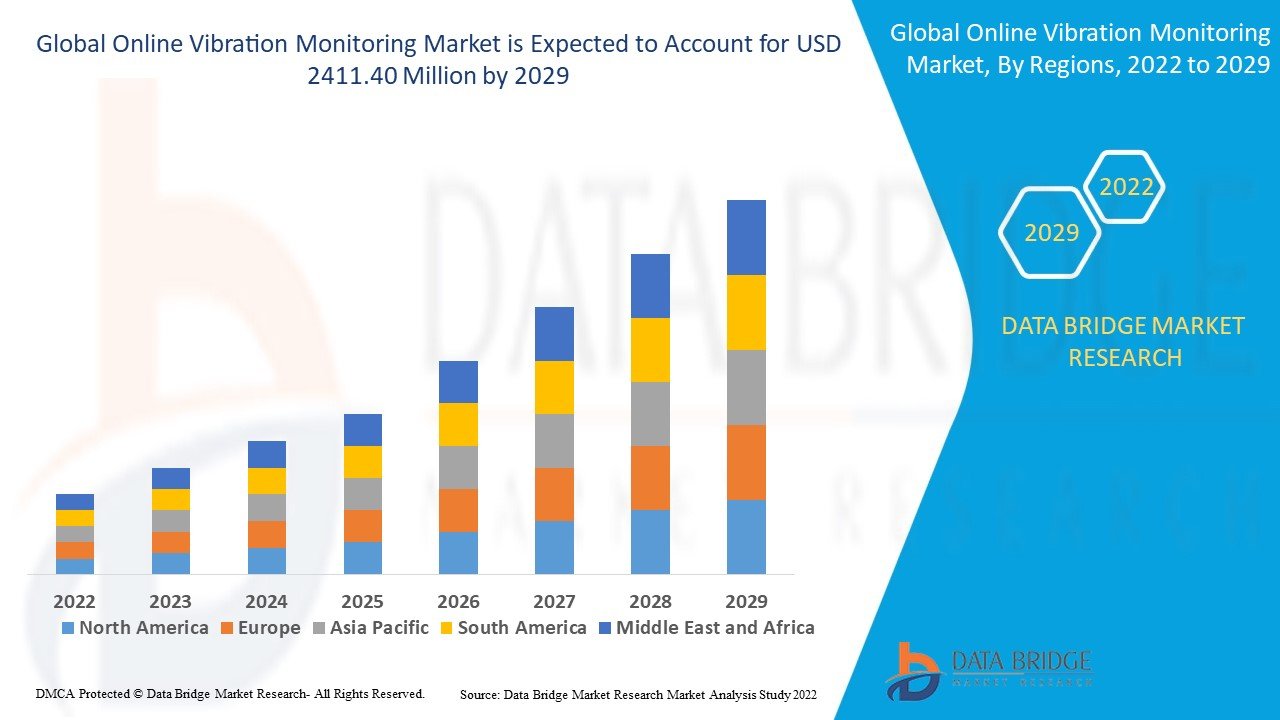

According to market insights, the online vibration monitoring market is projected to grow from USD 1,490.30 million in 2022 to USD 2,411.40 million by 2029, advancing at a CAGR of 6.20% during the forecast period, driven by rising demand for predictive maintenance, Industrie 4.0 adoption, and the need for continuous monitoring in critical operations.

Increasing Adoption of Online Vibration Monitoring in Industrial Operations

Online vibration monitoring systems allow companies to continuously track the condition of rotating machinery such as motors, turbines, pumps, compressors, generators, and gearboxes. Real-time data helps detect anomalies instantly, enabling maintenance teams to respond before failures occur. This approach significantly reduces unplanned shutdowns, improves machine reliability, and enhances overall productivity.

Request a sample of Online Vibration Monitoring Market report @ https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-online-vibration-monitoring-market

Industries such as oil & gas, manufacturing, energy & power, chemicals, mining, and aerospace heavily rely on heavy-duty equipment that must operate consistently and safely. Online vibration monitoring technologies provide valuable insights that help optimize processes, reduce maintenance costs, and extend asset lifecycles.

With the rise of smart factories and connected industrial systems, vibration monitoring is becoming more integrated with IoT platforms, cloud analytics, and artificial intelligence. This integration supports advanced diagnostics, predictive decision-making, and automated alerts, strengthening maintenance strategies across complex operations.

Key Drivers Supporting Market Growth

- Rising Demand for Predictive and Preventive Maintenance

Industries increasingly prioritize real-time monitoring to reduce failure risks and maintenance expenditures.

- Growing Focus on Equipment Reliability and Operational Safety

Continuous monitoring helps identify structural issues early, reducing the likelihood of accidents or equipment breakdowns.

- Expansion of Industrie 4.0 and Smart Manufacturing

IoT-enabled monitoring solutions enhance data accuracy, remote accessibility, and automated alerts.

- Increased Use of High-Value Rotating Machinery

Sectors such as power generation and oil & gas rely on critical equipment that requires constant oversight.

- Technological Advancements in Sensors and Analytics

Enhanced algorithms, wireless sensors, cloud platforms, and digital twins improve predictive capabilities.

Inquire here to explore industry-specific data @ https://www.databridgemarketresearch.com/inquire-before-buying?dbmr=global-online-vibration-monitoring-market

Major Applications of Online Vibration Monitoring

- Condition Monitoring

Real-time insights help maintenance teams track equipment health and maintain peak performance.

- Fault Detection and Diagnosis

Vibration trends reveal potential mechanical issues such as imbalance, looseness, or misalignment.

- Predictive Maintenance

Advanced analytics identify degradation patterns, enabling timely intervention to avoid downtime.

- Quality Assurance

Monitoring helps verify machine stability and accuracy during production.

- Remote and Automated Monitoring

Sensors and digital systems allow remote supervision of equipment even in hazardous environments.

Leading Companies Operating in the Online Vibration Monitoring Market

Prominent companies contributing to technology development, advanced analytics, and smart industrial solutions include:

- Emerson Electric Co.

- General Electric

- Honeywell International

- NATIONAL INSTRUMENTS CORP.

- SKF

These companies continue to innovate in vibration sensors, wireless monitoring systems, cloud-based analysis platforms, and end-to-end predictive maintenance solutions. Their advancements help industries achieve greater operational reliability, automation, and cost efficiency.

Emerging Trends Influencing the Online Vibration Monitoring Market

- AI-Driven Predictive Analytics

Artificial intelligence enhances fault prediction accuracy and supports automated maintenance decision-making.

- Increased Integration with IoT and Cloud Platforms

IoT connectivity enables seamless data transmission, storage, and centralized monitoring across remote assets.

- Adoption of Wireless and Battery-Free Sensors

New-generation sensors improve flexibility, reduce installation costs, and expand monitoring coverage.

- Growth of Edge Computing in Industrial Monitoring

Edge devices process vibration data locally for faster, real-time insights and reduced latency.

Importance of Online Vibration Monitoring in Modern Industry

Online vibration monitoring plays a vital role in ensuring equipment longevity, maintenance efficiency, and operational safety. Key benefits include:

- Early detection of mechanical faults

- Reduced production downtime and maintenance costs

- Enhanced worker safety

- Extended machinery life and performance optimization

- Real-time visibility into equipment condition

- Increased automation and reduced manual inspections

- Improved long-term asset management strategies

As industries undergo digital transformation, online vibration monitoring will continue to be a cornerstone of modern predictive maintenance frameworks.

Access the full Online Vibration Monitoring Market Report here @ https://www.databridgemarketresearch.com/reports/global-online-vibration-monitoring-market

For More Reports

Motor Testing Equipment Market

About Us

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact

Data Bridge Market Research Private Ltd.

3665 Kingsway — Suite 300

Vancouver BC V5R 5W2

Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)

Email: Sales@databridgemarketresearch.com

Website: https://www.databridgemarketresearch.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness