The Benefits of Choosing Quality CNC Machining Solutions for Your Projects

Choosing the right manufacturing partner is one of the most important decisions businesses make when transforming concepts into real-world products. In today’s competitive environment, the demand for precision, speed, and consistency is higher than ever, pushing industries to rely heavily on modern machining technologies. Among these advancements, quality CNC machining solutions stand out as the backbone of efficient production, supporting projects across automotive, aerospace, medical, electronics, consumer products, and more. High-quality CNC machining not only ensures superior performance but also helps companies bring products to market faster, reduce operational risks, and build long-term reliability in their manufacturing processes.

Whether you are developing a brand-new prototype or scaling up to mass production, the advantages of CNC machining go far beyond accuracy alone. Companies that prioritize quality solutions can achieve better cost control, improved structural integrity, and enhanced repeatability—factors that can ultimately determine the success or failure of a project. With global demand rising for meticulously engineered components, choosing quality CNC machining solutions has become a strategic move for those who want to stay ahead in their industry.

Unmatched Precision and Accuracy in Every Component

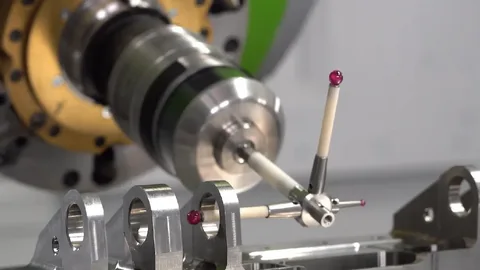

One of the most significant benefits of choosing quality CNC machining solutions is the level of precision these systems offer. Unlike traditional manual machining, CNC technology uses computer-controlled automation to achieve tight tolerances down to microns, making it ideal for industries where accuracy is critical. Whether it’s a medical implant or a complex aerospace component, CNC machines replicate every detail precisely as programmed, minimizing errors and reducing the risk of costly rework. This precision not only ensures product performance but also enhances overall safety and durability, which are crucial in high-stakes sectors.

Furthermore, top-tier CNC machining providers invest in advanced multi-axis equipment that allows complex geometries to be produced with ease. This capability expands the design possibilities and enables engineers to explore innovative shapes without compromising accuracy. With 3-axis, 4-axis, and 5-axis machining available, designers can create intricate parts that once seemed impossible to produce manually. This level of flexibility and exactness highlights why companies around the world rely heavily on quality CNC machining solutions for both simple and highly sophisticated projects.

Superior Consistency and Repeatability for Mass Production

Consistency is key when manufacturing multiple parts with identical features and performance specifications. High-quality CNC machining guarantees that every component produced matches the original design, regardless of volume. This repeatability ensures that whether you need ten parts or ten thousand, each unit will function exactly as intended. It eliminates human error and variability, making it an ideal solution for businesses that require dependable batch production. This reliability helps strengthen supply chain stability and supports long-term operational efficiency.

In addition, quality CNC machining solutions enhance production workflow by maintaining consistent performance across every manufacturing cycle. Advanced software integration allows machines to follow precise programming instructions repeatedly, ensuring the same outcomes every time. This level of uniformity is particularly valuable for industries like automotive or electronics, where even the smallest deviations can affect product performance or assembly compatibility. By choosing high-quality CNC services, businesses safeguard their production processes with dependable consistency.

Faster Production Times and Improved Efficiency

Speed is another crucial advantage of using quality CNC machining solutions. Computer-controlled machining significantly reduces production time by automating processes that traditionally required manual labor. The ability to run machines continuously—often 24/7—means projects can be completed far faster than conventional manufacturing methods. This quick turnaround is especially beneficial for rapid prototyping, where designers need immediate physical samples to test and refine their concepts.

Additionally, CNC machining eliminates downtime and minimizes delays by reducing tool changes, improving workflow organization, and providing predictable machining cycles. Advanced CNC systems are designed for high-speed operations without sacrificing accuracy, enabling businesses to accelerate product development while maintaining superior quality. Faster production also contributes to meeting tight deadlines, improving customer satisfaction, and staying competitive in fast-moving markets. Ultimately, this increased efficiency underscores the importance of choosing quality CNC machining solutions for any project requiring precision and speed.

Cost-Effective Manufacturing for Projects of Any Size

While some assume advanced machining technologies come with higher upfront costs, the long-term savings provided by quality CNC machining solutions make them highly cost-effective. Automated machining significantly reduces human labor, minimizes material waste, and lowers the likelihood of errors or rework. When parts are produced right the first time, businesses save both money and time throughout the manufacturing process. The efficiency of CNC machines also helps optimize material usage, ensuring the lowest waste possible with every cut.

Moreover, CNC machining reduces overhead costs by streamlining production and enhancing resource management. The ability to run machines with minimal supervision leads to lower labor expenses, while consistent quality reduces inspection and correction costs. Whether a project involves small prototype runs or large-scale production, choosing expert CNC machining services can lead to substantial financial benefits. These factors highlight why many companies view quality CNC machining solutions as an investment rather than an expense—an investment that pays off through long-term operational savings and improved profitability.

Enhanced Durability and Reliability for High-Performance Applications

A final but equally important advantage of choosing quality CNC machining solutions is the enhanced durability and reliability they deliver. High-quality machining ensures components meet strict structural standards and perform consistently under demanding conditions. For industries such as aerospace, medical device manufacturing, and defense, high-performance parts must endure intense stress, temperature variations, and operational pressure. CNC machining provides the strength and precision needed to create parts that can withstand these challenges without failure.

Additionally, quality machining ensures better surface finishes, stronger structural integrity, and improved lifetime performance. The ability to machine a wide variety of materials—including metals, plastics, composites, and advanced alloys—adds further versatility. This allows engineers to select materials that best suit their application without compromising on manufacturability or precision. With the increasing demand for durable, high-precision components, choosing quality CNC machining solutions helps businesses achieve reliable results that support product longevity and customer satisfaction.

Conclusion

Choosing quality CNC machining solutions for your projects offers a wide range of critical benefits, from superior precision and repeatability to faster production times and cost savings. These solutions help companies maintain high standards, reduce operational risks, and deliver products that meet the ever-increasing demands of global markets. Whether you're developing a new prototype or managing high-volume production, relying on expert CNC machining ensures that every component is crafted with accuracy, efficiency, and durability.

As industries continue to push boundaries with innovative designs and advanced materials, CNC machining remains an essential tool for turning ideas into reality. By investing in quality machining services, businesses position themselves for long-term success, enhanced product performance, and improved customer trust. In an era where reliability and precision matter more than ever, choosing quality CNC machining solutions truly makes a difference in every project.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness