Inside UAE Fabrication: The Role of Lathes in Advanced Metal Manufacturing

In the dynamic landscape of industrial manufacturing, fabrication companies in UAE play a critical role in sustaining the country’s infrastructure, energy, and marine sectors. Among the many processes that define their capabilities, lathe machining stands out as one of the most precise and versatile techniques in advanced metal manufacturing. From reshaping large shafts to restoring high-performance components, lathes remain the backbone of every serious fabrication and machining company in the UAE.

At the heart of this capability lies Daniel Group, an established electromechanical and fabrication company in the UAE, known for its in-house mechanical workshop, precision-driven workmanship, and more than three decades of service excellence. This article explores how lathes shape the core of metal fabrication in the UAE, how Daniel Group integrates these capabilities within its operations, and why this expertise continues to define industry standards for reliability and precision.

The Fabrication Landscape in the UAE

The UAE’s industrial sector thrives on efficiency, quality, and precision. Fabrication companies across Dubai, Sharjah, and Abu Dhabi serve diverse sectors such as oil and gas, power generation, marine, utilities, and heavy manufacturing. Each of these industries demands exacting standards—often requiring machining companies in UAE to deliver components with sub-millimetre accuracy and rapid turnaround.

A typical fabrication company in UAE must combine heavy-duty metal forming, machining, welding, and repair under one roof to remain competitive. These facilities often include a machine shop equipped with lathes, milling machines, dynamic balancing systems, and custom fabrication tools. The integration of these processes allows companies to maintain full control over quality and timelines, minimizing reliance on external subcontractors.

Within this ecosystem, Daniel Group’s machine shop stands as a model of operational integration. By combining electromechanical repair expertise with precision machining and fabrication, the company ensures that every project—from shaft manufacturing to gearbox repair—meets both mechanical and electrical performance requirements.

Why Lathes Matter in Metal Fabrication

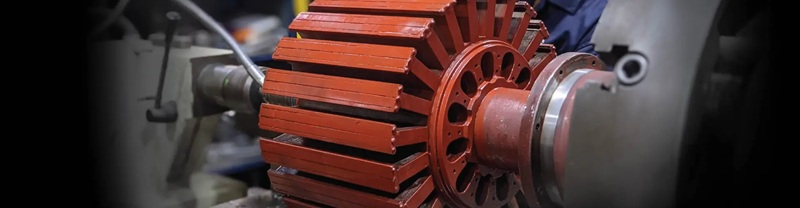

A lathe is one of the oldest and most essential tools in manufacturing, used to rotate a workpiece against cutting tools to achieve the desired shape. In modern metal fabrication, lathes have evolved into precision-controlled machines capable of producing highly accurate components across multiple materials and dimensions.

In the UAE’s industrial sector, lathe machining is critical for:

-

Shaft repairs and rebuilds: Used in motors, pumps, and turbines.

-

Threading and facing: To ensure perfect component fit in assemblies.

-

Cylindrical machining: For components like couplings, rotors, and casings.

-

Precision finishing: Achieving tight tolerances in high-performance parts.

Lathes are indispensable in every machine shop works operation because they provide both flexibility and precision. They support the entire fabrication workflow, from initial raw material processing to the final finishing stage before assembly or balancing.

For Daniel Group, lathe machining is more than just a process—it’s a precision discipline. The company’s workshop includes both manual and CNC-controlled lathes, enabling technicians to handle a wide range of applications, from emergency repairs to high-volume production. Each operation is supervised by experienced machinists who understand the unique challenges of industrial machinery and apply decades of expertise to every job.

Daniel Group’s Integrated Machine Shop Works

Daniel Group’s mechanical and fabrication workshop is a cornerstone of its operations. Located in Dubai Industrial City, the facility brings together a wide range of in-house services that cover mechanical, electrical, and electromechanical repair under one roof.

In-house Capabilities

-

Lathe machining and turning: Precision turning of shafts, impellers, couplings, and bearing housings.

-

Pump and gearbox repair: Machining worn-out shafts and realigning casings for perfect assembly.

-

Dynamic balancing: Ensuring vibration-free operation after machining or fabrication.

-

Metal fabrication and welding: Structural frame fabrication, base plates, and custom metal assemblies.

-

Component rebuilds: Shaft re-metalling, bushing replacements, keyway cutting, and surface finishing.

Every task is executed under the supervision of trained professionals with hands-on field experience. Unlike many machining companies in UAE, Daniel Group maintains full internal control over quality and scheduling. This reduces downtime and guarantees consistent workmanship—especially critical for industries where machinery failure can lead to costly delays.

From Raw Material to Finished Component – The Lathe Workflow

The workflow inside a professional fabrication company in UAE like Daniel Group is both structured and efficient. Each project follows a carefully managed sequence designed to achieve precision and reliability.

-

Material Inspection and Preparation

Raw materials or damaged components are inspected for dimensional accuracy, material integrity, and wear. Engineers determine the machining requirements—such as tolerance levels and surface finish specifications—before setup begins. -

Setup and Machining

The component is mounted on the lathe, and technicians select the appropriate cutting tools and parameters. In the case of CNC turning, digital programming ensures consistent accuracy and repeatability across multiple parts. -

Precision Turning and Profiling

During turning, facing, and threading operations, the machinist constantly monitors alignment, feed rate, and tool wear. This stage defines the dimensional accuracy and surface quality of the final component. -

Post-Machining Operations

Once machining is complete, the part undergoes dynamic balancing, polishing, and dimensional verification. Daniel Group’s machine shop ensures each component meets ISO and OEM specifications before reassembly. -

Assembly and Final Integration

The turned and balanced component is integrated back into its system—whether a motor, pump, or gearbox. This complete in-house cycle eliminates unnecessary handling and transportation, reducing lead times and risk.

Lathe Applications Across UAE Industries

Marine & Shipping

Vessels rely heavily on large-diameter shafts, propeller assemblies, and couplings that require regular machining. Daniel Group’s lathe services ensure precise alignment and surface finish, reducing vibration and extending service life in harsh marine conditions.

Oil & Gas

The oil and gas sector demands tight tolerances and durable finishes for pump and compressor components. Lathes are essential for refurbishing shafts, rotors, and seal housings to ensure reliable operation in high-pressure environments.

Power & Utilities

Power plants rely on machining companies in UAE for maintaining generator and turbine shafts. Daniel Group provides on-site and workshop-based lathe services to restore critical rotating equipment with minimal downtime.

Manufacturing & Construction

From structural fabrication to heavy machinery, Daniel Group’s machine shop supports diverse industrial clients requiring machine shop works such as turning, welding, and balancing.

Choosing the Right Lathe and Fabrication Partner in the UAE

Selecting the right fabrication company in UAE involves evaluating both technical capability and service reliability. When comparing machining companies in UAE, decision-makers should consider:

-

Machine capacity and versatility: Ability to handle various materials, diameters, and lengths.

-

Precision standards: Tolerance control, surface finish, and certification compliance.

-

Emergency response: 24/7 repair capability for urgent equipment failures.

-

Technical supervision: Experienced machinists and engineers overseeing all work.

-

Integrated workshop services: Machining, fabrication, balancing, and assembly in one facility.

Daniel Group fulfills all these parameters, positioning itself as a trusted partner that delivers measurable value across industries. Clients rely on its ability to restore critical components quickly and with precision that meets or exceeds OEM specifications.

Advantages of In-House Lathe Machining

Having in-house lathe machining capability gives fabrication companies in UAE a major advantage over subcontract-based competitors. The benefits include:

-

Reduced Downtime: Immediate repair capability without waiting for third-party availability.

-

Better Quality Control: Every operation supervised under one quality management system.

-

Faster Turnaround: Streamlined workflow from machining to assembly.

-

Cost Efficiency: Eliminating logistics and outsourcing costs.

-

Technical Consistency: Single-point accountability for machining accuracy.

At Daniel Group, these benefits are embedded into daily operations. The company’s emphasis on maintaining all core services internally ensures reliability, speed, and technical uniformity.

The Future of Lathe Technology in UAE Fabrication

As fabrication technology evolves, machining companies in UAE are adopting advanced CNC systems, automation, and predictive maintenance tools. Modern lathes integrate smart sensors and software to optimize tool wear, accuracy, and production speed.

Future trends shaping the UAE’s fabrication sector include:

-

Smart CNC lathes with real-time monitoring and digital twin simulations.

-

Hybrid turning centers that combine milling and drilling for complex geometries.

-

Sustainability in machining through energy-efficient motors and coolant recycling.

-

AI-driven predictive maintenance, improving uptime and extending machine life.

Daniel Group continues to modernize its operations to align with these trends, combining decades of experience with the precision of new-generation machine tools. This balance between traditional craftsmanship and modern technology defines its leadership in the regional fabrication industry.

A trusted partner in precision and reliability

Every turned shaft, balanced rotor, and repaired gearbox that leaves Daniel Group’s workshop represents more than technical accuracy—it embodies the company’s commitment to reliability, craftsmanship, and service integrity.

In a market where clients depend on zero-compromise performance, Daniel Group stands among the most dependable fabrication companies in UAE, offering end-to-end solutions under one roof. Its workshop remains a benchmark for machine shop works excellence, combining practical experience with the precision required in today’s advanced metal manufacturing landscape.

Daniel Group – setting the benchmark for fabrication companies in UAE through precision, integrity, and in-house expertise.

Frequently Asked Questions

1. What makes Daniel Group different from other fabrication companies in UAE?

Daniel Group combines electromechanical repair with complete machine shop works under one roof. Unlike many competitors, the company performs all machining, fabrication, and dynamic balancing in-house, ensuring consistent quality and faster delivery.

2. Does Daniel Group provide CNC machining and lathe turning services?

Yes. Daniel Group’s facility includes both manual and CNC-controlled lathes capable of precision turning, threading, and finishing for various industrial components such as shafts, rotors, and couplings.

3. Which industries benefit most from Daniel Group’s lathe and fabrication services?

The company serves oil & gas, marine, manufacturing, power generation, and utilities sectors—offering precision machining and fabrication for pumps, motors, generators, and gearboxes.

4. What is meant by machine shop works?

Machine shop works refer to in-house machining processes like lathe turning, milling, drilling, and dynamic balancing used to repair or manufacture metal components. Daniel Group’s mechanical workshop provides all these services.

5. Does Daniel Group offer emergency machining services in the UAE?

Yes. The company offers 24/7 emergency repair and machining support for clients across the UAE and GCC, ensuring critical operations resume quickly after unexpected failures.

6. How can clients request fabrication or machining support from Daniel Group?

Clients can contact Daniel Group through the official website or directly reach the Dubai Industrial City facility to schedule inspections, repairs, or fabrication projects.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness