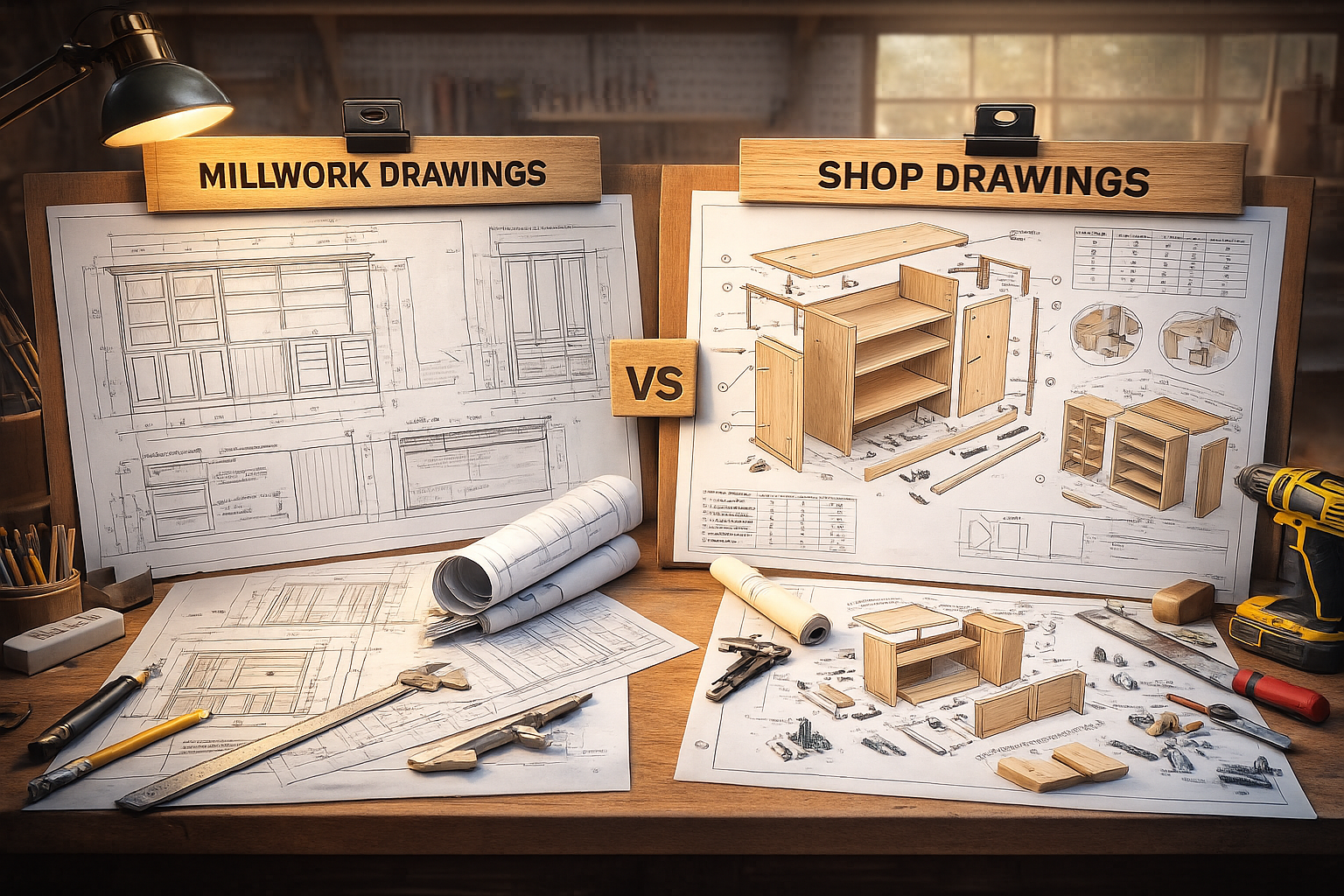

What Is the Difference Between Millwork Drawings and Shop Drawings?

In today’s fast-paced construction and interior fit-out landscape, precision is no longer optional it’s a necessity. From luxury commercial interiors in New York to high-end residential projects in London, one small drafting misinterpretation can snowball into delays, cost overruns, or material waste.

This is where millwork shop drawings and shop drawings come into play.

Yet, despite being widely used across architecture, engineering, and construction (AEC) projects, these two terms are often misunderstood or worse used interchangeably. For business owners, architects, engineers, and decision-makers, knowing the difference between millwork drawings and shop drawings can significantly impact project efficiency, quality, and profitability.

So, let’s break it down clearly, practically, and from a modern CAD industry perspective.

Why Do Millwork and Shop Drawings Matter More Than Ever in 2025?

According to a McKinsey construction productivity report, digital design and detailing can improve construction efficiency by up to 15% and reduce rework by nearly 30% when implemented correctly. This growing reliance on cad shop drawings reflects a broader shift toward precision-led construction.

In the USA and UK, stricter compliance standards, skilled labor shortages, and rising material costs have made accurate drawings a frontline defense against project risk.

What Are Shop Drawings?

Shop drawings are detailed, technical documents created by contractors, fabricators, or suppliers. They explain how specific components will be fabricated, assembled, installed, and coordinated on-site.

What Do Shop Drawings Typically Include?

Shop drawings services usually cover:

-

Dimensions and tolerances

-

Materials and finishes

-

Installation methods

-

Connection details

-

Fabrication instructions

-

Coordination with architectural and MEP plans

They act as the bridge between design intent and real-world construction.

Where Are Shop Drawings Used?

Shop drawings apply across multiple trades, including:

-

Structural steel

-

HVAC and ductwork

-

Electrical layouts

-

Plumbing systems

-

Joinery and interior components

In essence, shop drawings are universal, while millwork drawings are specialized.

What Are Millwork Drawings? (And Why They’re Different)

Millwork drawings focus specifically on custom woodwork and interior architectural elements. These drawings go far deeper into craftsmanship details than general shop drawings.

They are a subset of shop drawings, but with a much higher level of detail related to finishes, joinery, and aesthetics.

Typical Elements in Millwork Drawings

Millwork shop drawings usually include:

-

Custom cabinetry (kitchens, wardrobes, vanities)

-

Wall paneling and cladding

-

Reception desks

-

Display units and retail fixtures

-

Built-in furniture

-

Trim, molding, and decorative woodwork

They specify not just how something is built but how it looks and feels.

What Is the Core Difference Between Millwork Drawings and Shop Drawings?

Here’s the simplest way to understand it:

All millwork drawings are shop drawings, but not all shop drawings are millwork drawings.

Key Differences at a Glance

| Aspect | Shop Drawings | Millwork Drawings |

|---|---|---|

| Scope | Broad (multiple trades) | Specialized (woodwork only) |

| Detail Level | Functional & technical | Highly detailed & aesthetic |

| Focus | Installation & coordination | Craftsmanship & finishes |

| Materials | Steel, concrete, MEP, wood | Primarily wood & laminates |

| Audience | Contractors & installers | Fabricators & interior teams |

Why Are Millwork Shop Drawings So Critical for Interior Projects?

According to Dodge Construction Network, interior fit-out errors account for nearly 40% of rework costs in commercial projects. This is where millwork shop drawing services become invaluable.

Key Reasons Millwork Drawings Reduce Risk

-

They clarify design intent for fabricators

-

They eliminate assumptions about finishes and joints

-

They prevent costly on-site modifications

-

They ensure approval before fabrication begins

For high-end hospitality, retail, and corporate interiors in the USA and UK, millwork drawings are not optional they are essential.

How Do CAD Shop Drawings Improve Accuracy and Collaboration?

Modern cad shop drawings go far beyond 2D lines.

Current CAD Trends in the USA & UK

-

3D modeling for clash detection

-

BIM-integrated shop drawings

-

Parametric detailing for millwork

-

Cloud-based collaboration and approvals

A study by Autodesk shows that BIM-enabled shop drawings reduce coordination errors by up to 35%, especially in complex interior projects.

CAD-based workflows also enable:

-

Faster revisions

-

Clearer communication

-

Better visualization for non-technical stakeholders

When Should You Use Shop Drawings vs. Millwork Drawings?

Use Shop Drawings When:

-

Coordinating multiple trades

-

Installing structural or MEP components

-

Managing complex site conditions

-

Ensuring code compliance

Use Millwork Shop Drawings When:

-

Fabricating custom interiors

-

Working on premium or luxury projects

-

Managing tight tolerances

-

Ensuring finish accuracy

Most large projects require both, working together seamlessly.

What Are the Biggest Challenges in Millwork and Shop Drawings Today?

Despite advancements, challenges remain.

1. Design-to-Fabrication Gaps

Architectural drawings often lack fabrication-level details. Without proper millwork drawings, fabricators are forced to interpret leading to errors.

2. Skilled Labor Shortages

The U.S. Bureau of Labor Statistics highlights an ongoing shortage of skilled drafting professionals. This has increased reliance on outsourced shop drawings services, particularly from the UK and global CAD hubs.

3. Tight Timelines and Fast-Track Projects

Compressed schedules leave little room for revision. Accurate drawings upfront are critical.

Why Are Outsourced Shop Drawings Services Growing in the USA and UK?

Outsourcing is no longer about cost alone it’s about expertise and scalability.

Benefits of Outsourcing CAD and Millwork Drawings

-

Access to specialized millwork expertise

-

Faster turnaround times

-

Compliance with US & UK standards

-

Scalable resources during peak workloads

According to Statista, the global CAD outsourcing market is expected to grow at over 7% CAGR, driven largely by construction digitization.

How Do Millwork Shop Drawings Support Sustainable Construction?

Sustainability is becoming a priority in both the USA and UK.

Well-prepared millwork drawings:

-

Reduce material waste

-

Optimize panel cutting layouts

-

Support FSC-certified wood usage

-

Minimize rework and landfill waste

This aligns with LEED and BREEAM sustainability goals, making millwork drawings an indirect but powerful green construction tool.

Are Millwork Drawings Important for Approvals and Compliance?

Absolutely.

Millwork shop drawings are often required for:

-

Client approvals

-

Architect sign-offs

-

Compliance verification

-

Fabrication authorization

Without approved drawings, many fabricators will not proceed protecting all stakeholders legally and financially.

Choosing the Right Drawing Approach

Understanding the difference between millwork drawings and shop drawings isn’t just technical knowledge it’s a strategic advantage.

In today’s competitive construction environment, especially across the USA and UK, accurate documentation determines whether a project stays on track or spirals into delays.

Shop drawings ensure everything fits and functions.

Millwork shop drawings ensure everything looks right and builds right.

Conclusion:

As projects grow more complex and timelines tighter, working with experienced CAD professionals becomes essential. Many architects and contractors now collaborate with a leading UK CAD design company that understands international standards, modern workflows, and the craftsmanship behind high-quality millwork.

When precision, clarity, and coordination matter the right drawings make all the difference.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness