Unlocking Efficiency with Process Control Devices in Industrial Systems

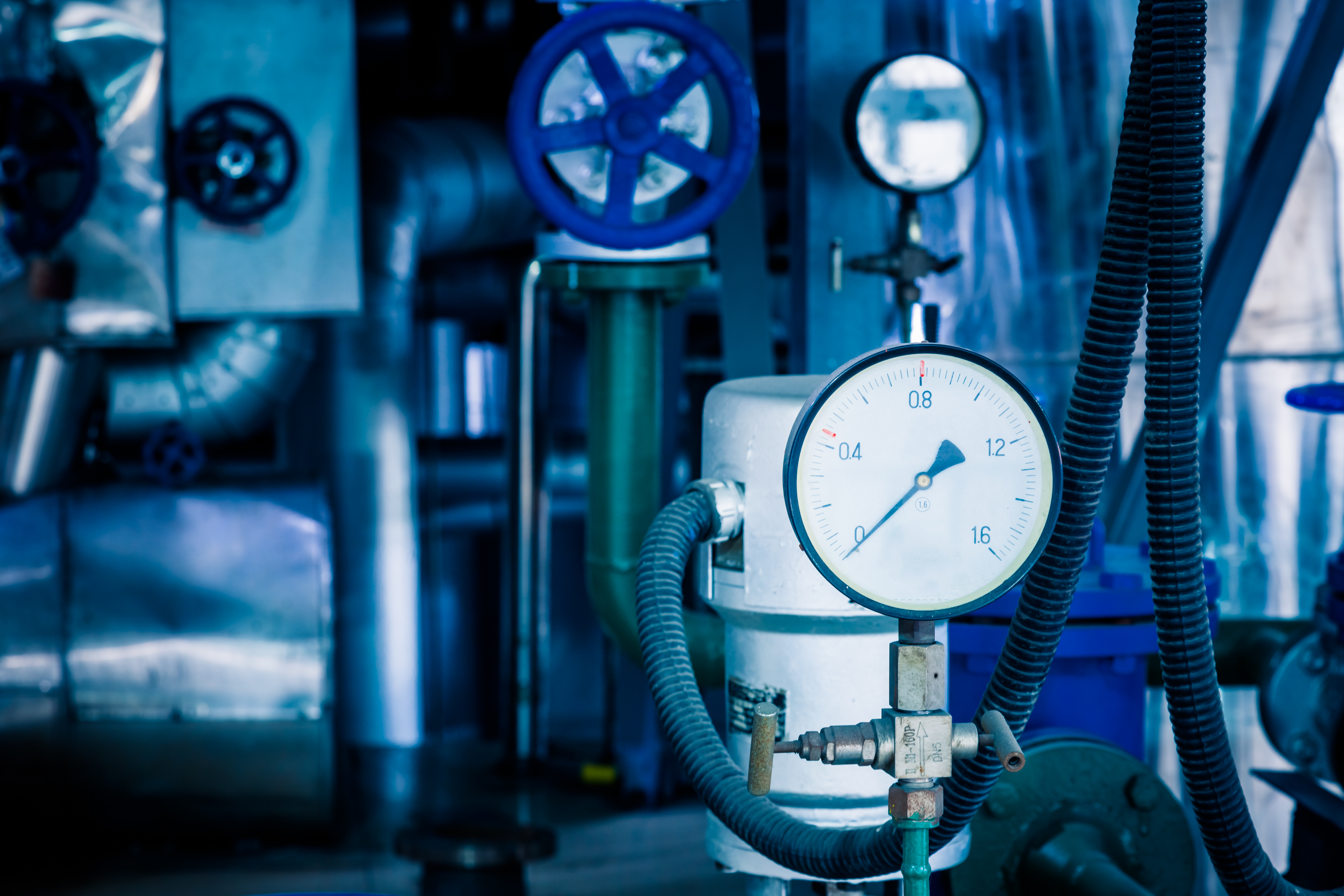

In today’s fast-paced industrial environment, achieving consistent product quality, maximum operational efficiency, and robust safety has never been more critical. That’s where process control devices come into play. These devices form the heart of modern automation systems, enabling precise regulation of variables like temperature, pressure, flow, and level. They help industries maintain control and achieve smooth operations without constant manual intervention.

What Are Process Control Devices?

Process control devices are components that monitor and regulate various industrial processes. They include sensors, transmitters, controllers, valves, and actuators that work together to maintain balance in operations. Their primary purpose is to keep process variables within desired ranges, ensuring consistent and efficient outcomes.

Why They Are Important for Industry

Using process control devices offers several advantages. They improve product quality by maintaining stable conditions, reduce waste through better process management, and enhance safety by triggering automatic responses during abnormal situations. These devices also help achieve higher operational efficiency and ensure regulatory compliance across industries.

Integration with Process Instrumentation

Process control devices work in close connection with instrumentation systems. Instruments like flow meters, level sensors, and pressure transmitters collect data from processes and send it to controllers, which then determine necessary adjustments. To learn more about how these systems work together, explore process instrumentation solutions designed to enhance process performance.

Applications Across Industries

In the food and beverage sector, process control devices ensure consistent mixing and temperature control. In pharmaceuticals and chemicals, they maintain safe reaction conditions. In water treatment plants, they help control flow, chemical dosing, and purification levels. Every industry that depends on precision and consistency benefits from effective process control.

Key Factors to Consider When Choosing Devices

When selecting process control devices, focus on accuracy, durability, and compatibility. The devices should be capable of operating within the expected temperature and pressure ranges, withstand harsh conditions, and communicate effectively with other system components. Regular maintenance and calibration are also crucial for long-term reliability and performance.

Conclusion

Process control devices play a vital role in improving productivity, quality, and safety in modern industries. By combining advanced instrumentation with reliable control systems, industries can optimize processes and achieve sustainable growth. For detailed information about available instrumentation solutions, visit https://www.toshniwal.net/products/process-instrumentation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness